Loading... Please wait...

Loading... Please wait...Popular Brands

Our Newsletter

- Home

- ZDDPlus Oil Additives

ZDDPlus Oil Additives

ZDDPlus Oil Additive, is designed for car engines before 1989.

ZDDPlus™ is a product offered by car enthusiasts

to meet the needs of classic car aficionados.

“The automotive industry in general is changing in response to the environmental and financial pressures of today, with little concern for the classic car industry. We are engineers and automotive technicians by trade, and bring many years of problem solving experience to the task of keeping our classic cars operational and running better than new. We hope that one of the solutions we have designed for our own use will meet your needs as well. We have developed ZDDPlus™ to address the needs of classic car owners for an oil that will meet the specifications of the original oil for which their engines were designed.”

Why do we need ZDDPlus™?

As part of an effort to reduce vehicle emissions, the U.S. EPA offers vehicle manufacturers "credits" for early implementation as well as penalties for violation of emission reduction standards. The EPA's program called for 100,000-mile catalytic converter life by 2004, 120,000 miles by 2007, and 150,000 miles by 2009. To achieve these goals, automotive manufacturers have pressured their oil suppliers to remove substances from motor oils that would shorten the service life, including the proven EP (extreme pressure) additive ZDDP (zinc dialkyldithiophosphate). Zinc and phosphorus from the ZDDP can be present in small amounts in the exhaust gas of an engine depending on the amount of oil which is consumed in combustion. These elements can coat the catalyst reducing the amount of catalyst exposed to the exhaust gases, ultimately increasing emissions at the tailpipe. As a result of the EPA mandate, the ZDDP level in engine oils has been declining since the mid-1990s, roughly coinciding with the implementation of OBDII.

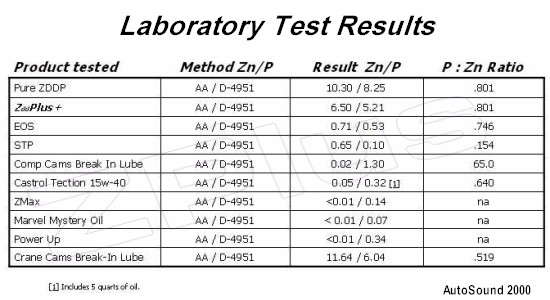

ZDDP has been an important additive to engine oils for over 70 years, and has an excellent track record at protecting the sliding metal-to-metal cam lifter interface. Historically, ZDDP has been added to oils in amounts resulting in approximately 0.15% phosphorus, and 0.18% zinc. ZDDP protects by creating a film on cams and flat lifter contact points in response to the extreme pressure and heat at the contact point. The film of zinc and phosphorus compounds provides a sacrificial wear surface protecting the base metal of the cam and lifter from wear. In the course of normal service, this conversion of ZDDP to zinc and phosphorus compounds depletes the ZDDP level in the oil. Studies show that depending on the specific engine and severity of duty, after 2000-4000 miles of operation, the level of ZDDP can drop below that considered adequate to provide wear protection to the cam and lifters.

According to the SAE Tech Bulletin # 770087[1], operation of a flat tappet engine without adequate EP additives such as ZDDP quickly leads to lifter foot scuffing and cam lobe wear. Camshafts are typically only surface hardened leaving the core ductile for strength. According to the SAE Bulletin, once cam lobe wear reaches 0.0002, "subsequent wear is usually rapid and catastrophic." Two ten-thousandths of an inch is one fifth the thickness of an average human hair.

In order to make engines last in the absence of ZDDP, virtually all IC (internal combustion) engines designed in the last ten years utilize roller lifters. Today, ZDDP has been removed from practically all automotive engine oils, rendering them unsuitable for use with older engines with non-roller lifters.